新闻资讯

NEWS

Introduction to the Properties of Ultra-high Molecular Weight Polyethylene Pipes

Introduction to the Properties of Ultra-high Molecular Weight Polyethylene Pipe

1. Wear Resistance: The wear resistance of ultra-high molecular weight polyethylene (UHMWPE) pipes is more than 8 times that of medium carbon steel and more than 5 times that of nylon 66. Data obtained through slurry erosion wear tests on lining materials using a slurry wear testing machine are shown in Table 1:

Table 1: Erosion Test Wear Rate

|

Material |

Sample No. |

Sample Flow Rate/(m/s) |

||||

|

1.8 2.4 3.2 4.0 4.8 |

||||||

|

UHMWPE |

1 |

17·436 |

22·548 |

26.814 |

30·435 |

33·926 |

|

2 |

17.6lO |

23.135 |

27.386 |

31.026 |

34.157 |

|

|

3 |

17.363 |

22.637 |

26.836 |

30.504 |

33.840 |

|

|

Average |

17.470 |

22.773 |

27.012 |

30.655 |

33.974 |

|

|

45#钢 |

7 |

132.667 |

175.596 |

204.365 |

246.597 |

270.130 |

|

8 |

134.850 |

178.334 |

2lO.702 |

251.018 |

275.334 |

|

|

9 |

129.776 |

168.266 |

199.853 |

242.49l |

267.862 |

|

|

Average |

132.431 |

174.065 |

204.973 |

246.7.2 |

271.109 |

|

Corrosion Resistance: Ultra-high molecular weight polyethylene is an inert material that can withstand corrosion from various chemical media, including strong acids and alkalis, except for a few strong oxidizing agents. Its chemical resistance properties are shown in Table 2:

Table 2: Chemical Resistance of Ultra-high Molecular Weight Polyethylene

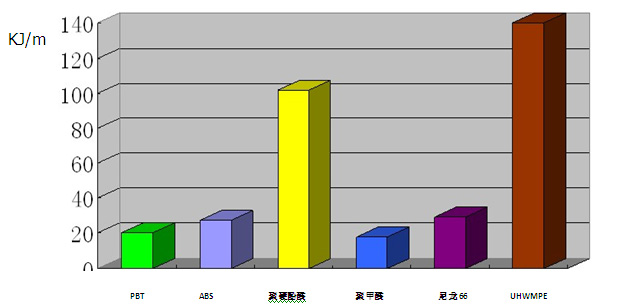

Impact Resistance: The impact strength of ultra-high molecular weight polyethylene is currently the highest among plastics, being 3-5 times higher than polycarbonate, which is known for its impact resistance. The impact strength of ultra-high molecular weight polyethylene and other engineering plastics is shown in Figure 5

Figure 4: Impact Strength of Engineering Plastics4. High Tensile Strength: With a tensile strength exceeding 23MPa and a tensile elastic modulus reaching 100-125GPa, it effectively solves the problem of easy peeling of the lining's flanged edges.

5. Heat Preservation and Viscosity Reduction: With a thermal conductivity that is 1/20th of steel, it exhibits excellent thermal insulation properties. Oil pipelines lined with ultra-high molecular weight polyethylene can significantly reduce heat loss during fluid flow, lowering the viscosity of crude oil.

6. Scale and Salt Prevention: Due to its low friction coefficient and non-polarity, the ultra-high molecular weight polyethylene lining material has excellent surface non-adhesiveness, making it highly resistant to sticking. Even when transporting complex fluid media, it won't form scale or salt deposits.

7. Anti-aging: The theoretical service life of the ultra-high molecular weight polyethylene lining material can reach over a hundred years. The aging and embrittlement rates are very slow, and under natural sunlight conditions, its service life exceeds 50 years.

8. Water-resistant: It is almost water-resistant and does not expand in water.

9. Good Self-lubricating Properties: With a friction coefficient smaller than other engineering materials, comparable to that of ice, it has good self-lubricating properties. This can reduce resistance, improve gathering and transportation capabilities, and minimize sediment.

10. Good Environmental Adaptability: It can operate in environmental temperatures ranging from -50℃ to +100℃ for extended periods.